When you notice rust spots appearing on your metal carport, garden fence, or small tool shed, are you troubled by how to deal with rust on steel structures?Hiring a professional team is costly, but ignoring the problem will only accelerate corrosion and compromise safety. In fact, through systematic DIY maintenance, you can effectively slow down or even halt the spread of rust.This article outlines a clear, actionable six-step method for rust and corrosion prevention in steel structures, empowering you to safeguard the longevity and strength of metal components with your own hands.

Step 1: Structural Steel Safety Assessment and Preparation

Safety always comes first before starting any work. First, thoroughly inspect the overall condition of the steel structure, identify all rusted areas, and assess their severity.For cases involving severe structural rust, deformation, or damage to critical load-bearing components, DIY repairs may pose risks. It is recommended to consult a professional. If the rust is limited to the surface or moderate in severity, repairs may proceed.Prepare personal protective equipment (PPE): safety goggles, dust mask, abrasion-resistant gloves, and work clothes. Simultaneously gather tools: wire brush, angle grinder (with rust-removal grinding disc), sandpaper, scraper, cleaning cloth, etc.

Step 2: Deep Rust Removal Treatment for Steel Structures

Surface preparation is the most critical step determining the success of corrosion protection, accounting for approximately 70% of the overall work quality. All loose, peeling old paint layers and surface rust must be thoroughly removed.

- Mechanical rust removal: For extensive rust coverage, use an angle grinder with a wire brush wheel or grinding disc for efficient grinding until the bare metal surface is exposed. Handheld wire brushes and scrapers can be used for hard-to-reach corners and edges.

- Chemical Rust Removal: For complex shapes or hard-to-reach crevices, use a specialized rust remover for steel structures. Apply according to instructions, allow it to fully react with the rust layer, then thoroughly rinse with clean water and air-dry.

- The post-treatment standard is: surfaces must achieve St2 grade (thorough manual and power tool rust removal) or higher, free of visible grease, dirt, loose scale, and rust layers.

Step 3: Steel Structure Surface Cleaning and Environmental Control

After rust removal, metal surfaces retain significant dust and impurities. Thoroughly remove all residues using brushes, vacuum cleaners, or high-pressure air. Subsequently, wipe the surface with a cloth soaked in specialized metal cleaner or diluted industrial alcohol to eliminate grease and fingerprints invisible to the naked eye. The construction environment is equally critical. Ensure the work area is well-ventilated, with ambient temperatures between 5°C and 35°C (41°F and 95°F), relative humidity below 85%, and avoid outdoor operations during rain, fog, or high-wind conditions.

Step 4: Selection and Preparation of Anti-Corrosion Coatings for Steel Structures

Select an appropriate anti-corrosion coating system based on the steel structure’s usage environment (indoor, outdoor, coastal, chemical exposure) and specific location. Common DIY-friendly solutions include:

- Primer: Epoxy zinc-rich primer or zinc phosphate primer is preferred for their superior rust prevention and adhesion.

- Topcoat: Choose acrylic polyurethane topcoat (high weather resistance) or alkyd enamel (versatile and economical).

Strictly follow product instructions for paint mixing. For two-component products, mix in precise proportions and stir thoroughly. Pay attention to the paint’s pot life and working time to avoid mixing excessive quantities at once, which leads to waste.

Step 5: Proper Application of Anti-Corrosion Coatings for Steel Structures

The quality of coating application directly impacts the protective lifespan.

- Application Methods: For DIY projects, brush and roller application are preferred. Brush application is suitable for complex areas such as edges, corners, and weld seams; roller application is ideal for large flat surfaces and offers high efficiency. Spray application yields the best results but requires specialized equipment and advanced skills.

- Key Coating Guidelines: Ensure primer fully covers the metal surface with no missed areas. Allow the primer to reach the specified surface-dry/through-dry time before applying subsequent coats. Typically, a complete protective system requires the coordinated use of primer, intermediate coat (if required), and topcoat. Avoid excessive thickness in each coat; uniform coverage is optimal.

Step 6: Inspection and Post-Application Maintenance of Steel Structure Anti-Corrosion Coatings

After construction is complete, inspect the paint film for uniformity, full coverage, absence of sagging, and no bare spots. The coating must be fully cured (typically requiring about 7 days to achieve optimal performance) before normal use is permitted.

Steel structure corrosion protection is not a permanent solution. Establish a simple routine inspection system, conducting at least one comprehensive annual inspection with a focus on welds, joints, and areas prone to water accumulation. If localized paint film damage or new rust spots are discovered, promptly sand away the rust, clean the surface, and apply a fresh coat of the same series of paint to prevent corrosion from spreading.

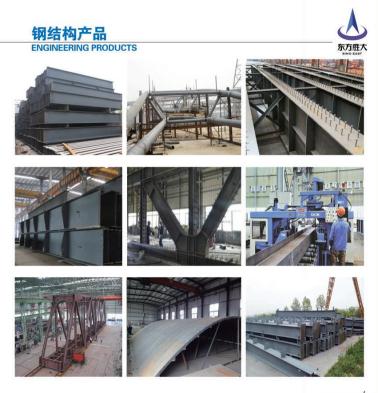

After completing the above guide,if you are seeking a steel structure manufacturer capable of meeting high standards across the board, Sino East Steel Enterprise co.,Ltd is well worth your closer examination.

As a seasoned steel structure manufacturer with 17 years of industry experience, the company consistently prioritize safety and quality above all else:

1. Full Qualifications: We hold ISO Quality Management System Certification. Recognized as a high-tech enterprise by local authorities, we ensure compliance from the source.

2 Full-Process Quality Monitoring: A comprehensive management system has been established covering laboratory R&D, raw material procurement, manufacturing, monitoring and control, transportation, and after-sales service.

3 Full-Process Service: We not only provide high-quality steel structure products, but also offer full-cycle services ranging from design support and installation guidance to long-term maintenance,serving as a reliable partner for your projects.

We believe that true reliability stands up to scrutiny at every step of the process.

Conclusion

By following these six steps, you can confidently undertake rust and corrosion prevention projects for household or small-scale steel structures. The key lies in patience and meticulousness, particularly during surface preparation—never cut corners.For large-scale, complex, or load-bearing critical steel structure corrosion protection projects, engaging a professional manufacturer with comprehensive qualifications and systems like ours is the wiser choice to ensure long-term safety and cost-effectiveness.