During the planning phase of constructing a factory building, selecting the appropriate building structure is often the first major decision facing owners. Steel structures and concrete structures are currently the two most mainstream choices for industrial factory construction, each offering unique advantages and suitable applications. This article will delve into six key factors influencing this decision, helping you make the choice best suited to your specific needs.

Key Factor 1: Construction Cost Comparison Analysis

Construction costs represent the most direct consideration in factory building projects, typically divided into two aspects: initial construction costs and long-term holding costs.

Steel-structured factory buildings often possess certain advantages during initial construction. Their material costs are relatively controllable, and most components can be prefabricated in factories, enabling rapid on-site assembly that significantly reduces labor and time costs. Generally, the construction cycle for steel-structured factory buildings is shortened by 30%-50% compared to concrete structures. This translates to earlier production commencement and faster capital recovery.

The initial material costs for concrete-structured industrial buildings may be relatively low, but their extended construction periods, complex formwork engineering, and substantial on-site labor requirements result in significant overall construction costs that cannot be overlooked. However, concrete structures typically feature lower long-term maintenance expenses and extended service life, potentially offering greater advantages in long-term holding costs.

For businesses with limited budgets seeking rapid production ramp-up, steel structures often present a more attractive option.

Key Factor 2: Construction Period and Commissioning Timeline

Time is money, and this principle is particularly evident in factory construction.

The construction cycle for steel structures is significantly shorter. Since major components are prefabricated in factories, on-site work primarily involves assembly. The foundation construction and main structure installation for a medium-sized factory building can be completed within 3 to 6 months. This rapid construction capability enables enterprises to commence production sooner and seize market opportunities.

The construction cycle for concrete structures is relatively lengthy. From foundation work, formwork erection, and rebar tying to concrete pouring and curing, each phase requires ample time. For facilities of comparable scale, concrete structures typically take 8 to 12 months or even longer to complete.

If the project timeline is tight, steel structures are undoubtedly the superior choice; if time is relatively flexible and greater emphasis is placed on the building’s permanence and stability, concrete structures are worth considering.

Key Factor 3: Structural Performance and Spatial Flexibility

Different production activities impose varying demands on factory space and structural performance.

Performance characteristics of steel structures: High strength and light self-weight enable large-span spatial designs with minimal internal column grids and high space utilization. This flexibility makes them ideal for businesses requiring large equipment, spacious operational areas, or potential future adjustments to production layouts. Steel structures also offer excellent seismic resistance, making them the preferred solution in earthquake-prone regions.

Performance characteristics of concrete structures: Excellent durability, superior fire resistance, and strong sound insulation. Concrete industrial buildings exhibit good thermal inertia, resulting in minimal indoor temperature fluctuations, which benefits certain temperature-sensitive production environments. However, their spans are relatively limited, and the presence of numerous internal columns may impact equipment layout and logistics efficiency.

Key Factor 4: Facility Lifespan and Maintenance Requirements

The lifespan and maintenance costs of a building directly impact a company’s long-term return on investment.

The service life of steel structures is generally over 50 years, but regular maintenance is required, particularly anti-corrosion treatment. Coatings should be inspected and maintained every 5 to 10 years, with this interval potentially shortened in humid or corrosive environments. Roofing systems also require periodic maintenance to prevent leaks.

Concrete structures can have a service life of 70 to 100 years or even longer, with relatively low maintenance requirements. They offer strong corrosion resistance and do not require the frequent protective treatments needed for steel structures. However, concrete may develop cracks, necessitating regular inspections and repairs, particularly in regions with significant temperature fluctuations.

Key Factor 5: Environmental Sustainability Considerations

As environmental regulations become increasingly stringent, the green attributes of factory buildings have also become a critical consideration.

Steel structures offer significant environmental advantages: materials are 100% recyclable, construction sites generate minimal noise and dust, making it a green construction method. Prefabricated production reduces on-site waste, aligning with the principles of a circular economy.

Environmental characteristics of concrete structures: Materials are widely available, but cement production consumes significant energy and generates substantial carbon emissions. However, concrete offers excellent thermal properties that reduce operational energy consumption in industrial buildings. Its durability minimizes reconstruction needs, contributing to environmental benefits over its entire lifecycle.

Key Factor 6: Industry Suitability and Future Development

Different industries have varying requirements for factory buildings, and future development needs should also be considered in advance.

Steel structures are suitable for logistics warehousing, light manufacturing, machinery production, automotive industries, and other sectors requiring large spaces with potential production line adjustments. Their adaptability to expansion and modification makes them ideal for growing enterprises.

Concrete structures are suitable for industries with stringent requirements for cleanliness and stable temperature and humidity conditions, such as chemical processing, food manufacturing, and precision instrument production. They are also well-suited for constructing high-rise or multi-story industrial buildings.

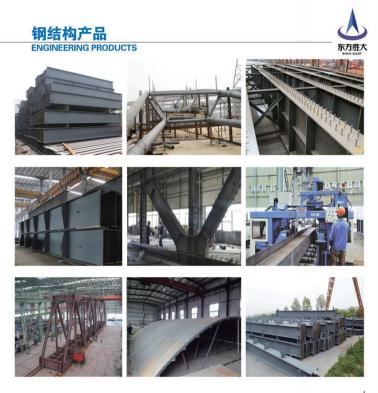

After the above analysis,if you are seeking a steel structure manufacturer capable of meeting high standards across the board, Sino East Steel Enterprise co.,Ltd is well worth your closer examination.

As a seasoned steel structure manufacturer with 17 years of industry experience, the company consistently prioritize safety and quality above all else:

1. Full Qualifications: We hold ISO Quality Management System Certification. Recognized as a high-tech enterprise by local authorities, we ensure compliance from the source.

2 Full-Process Quality Monitoring: A comprehensive management system has been established covering laboratory R&D, raw material procurement, manufacturing, monitoring and control, transportation, and after-sales service.

3 Full-Process Service: We not only provide high-quality steel structure products, but also offer full-cycle services ranging from design support and installation guidance to long-term maintenance,serving as a reliable partner for your projects.

Conclusions and Recommendations

The decision between steel and concrete structures should ultimately be based on a comprehensive assessment of the enterprise’s specific circumstances:

1. Enterprises with clear short-term needs, limited budgets, and urgent production requirements tend to opt for steel structures.

2. Businesses planning long-term occupancy, operating in stable industries, and requiring permanent facilities may find concrete structures more suitable.

3. For companies anticipating future expansion or renovation needs, steel structures offer distinct advantages in flexibility.

4. Special environmental requirements (such as corrosive conditions or high cleanliness standards) may dictate the choice of structural system.

It is recommended that before making a decision, professional structural engineers and architects be invited to conduct on-site inspections and compare detailed proposals. Comprehensive consideration should be given to initial investment, operational costs, maintenance expenses, and future development needs to make the decision that best aligns with the company’s long-term interests.

Regardless of the structural choice, selecting an experienced construction team and strictly controlling material quality and workmanship are key to ensuring the safety, durability, and cost-effectiveness of the factory building.